On some of the side projects that i was working for, a need for a large laser cutter became apparent. Unfortunately after some research, it became apparent too, that my options were 3:

- Get an epilog, which would be a great choice, if it wasn’t 3 times as expensive here as it is in the states

- Get a Chinese laser cutter and spend a lot time repairing its shortcomings

- Use an open source design

I decided to use the option 3, which, again, unfortunately created some issues, since there were only 2 choices.

- The buildlog 2.0, which had many components in imperial units that were on now defunct stores, and some questionable design choises

- and the lasersaur, which relied on expensive components which made its selection in relation of an OEM machine, questionable

In the end i decided that the best course of action would be to spend a week and design my own version according to me specifications:

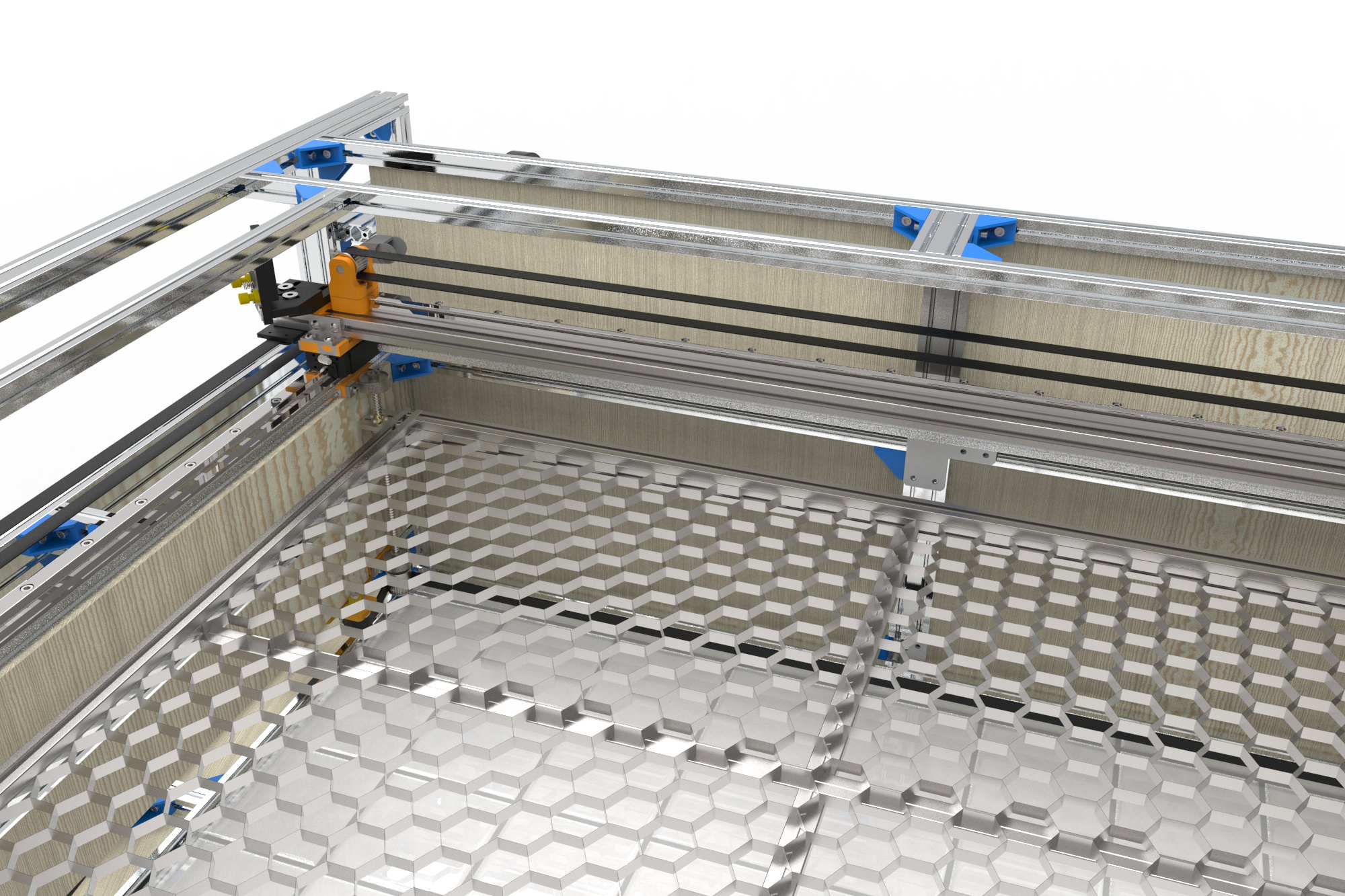

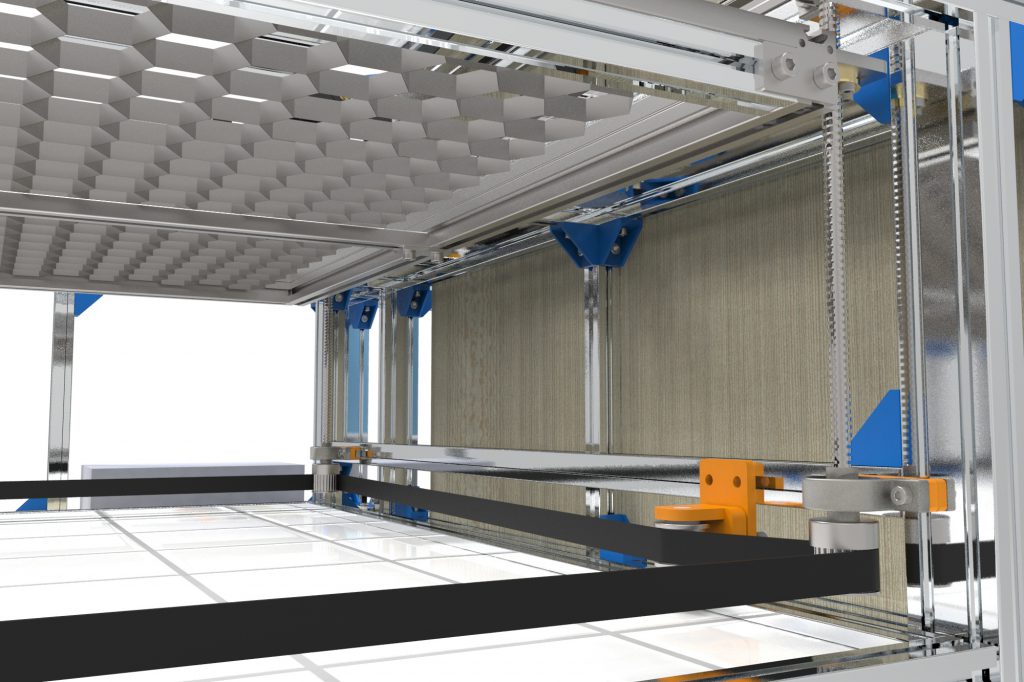

- Large cutting area, at least 1000x600mm.

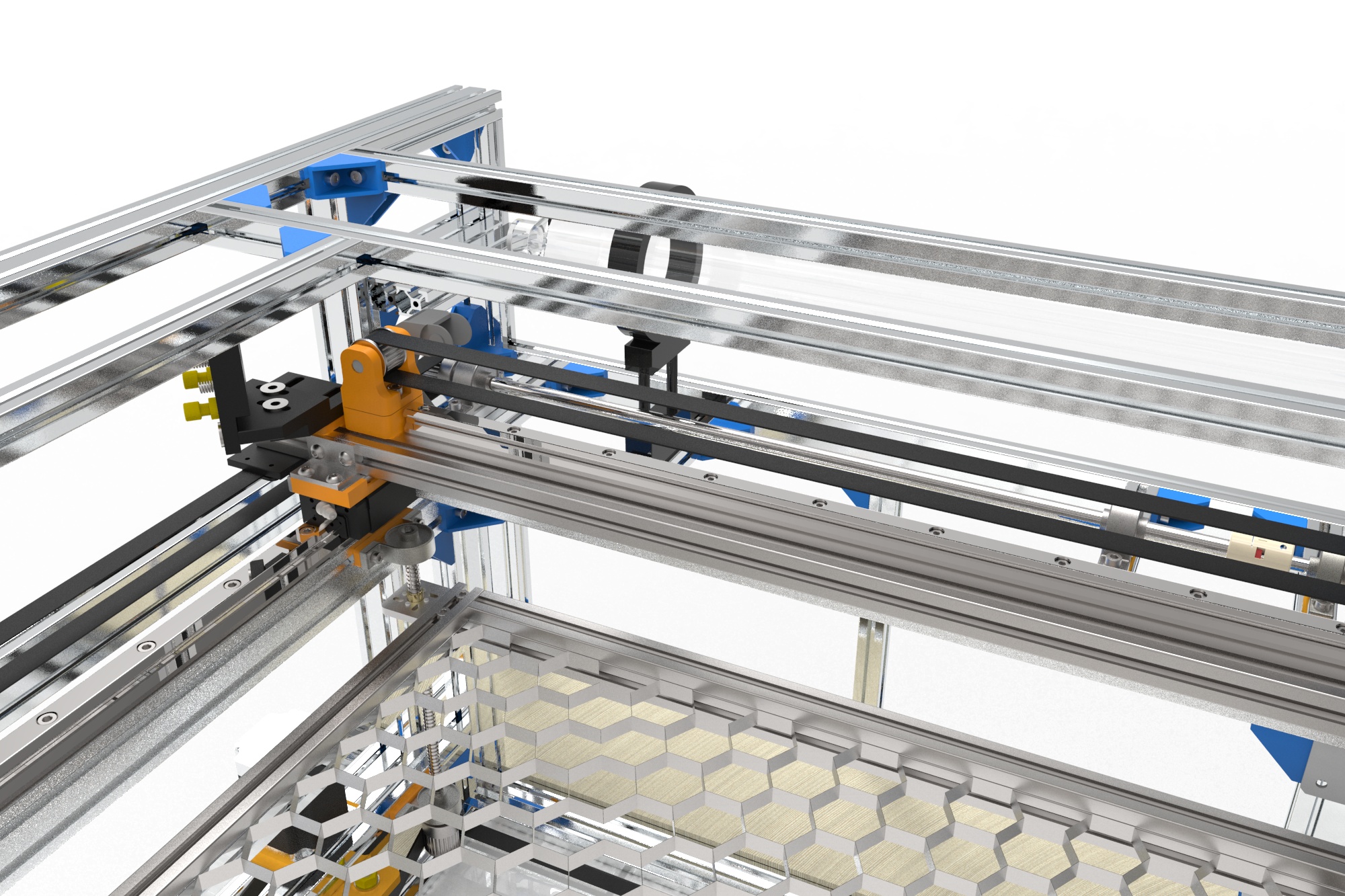

- OEM DSP laser controller, so i dont have to reinvert the wheel.

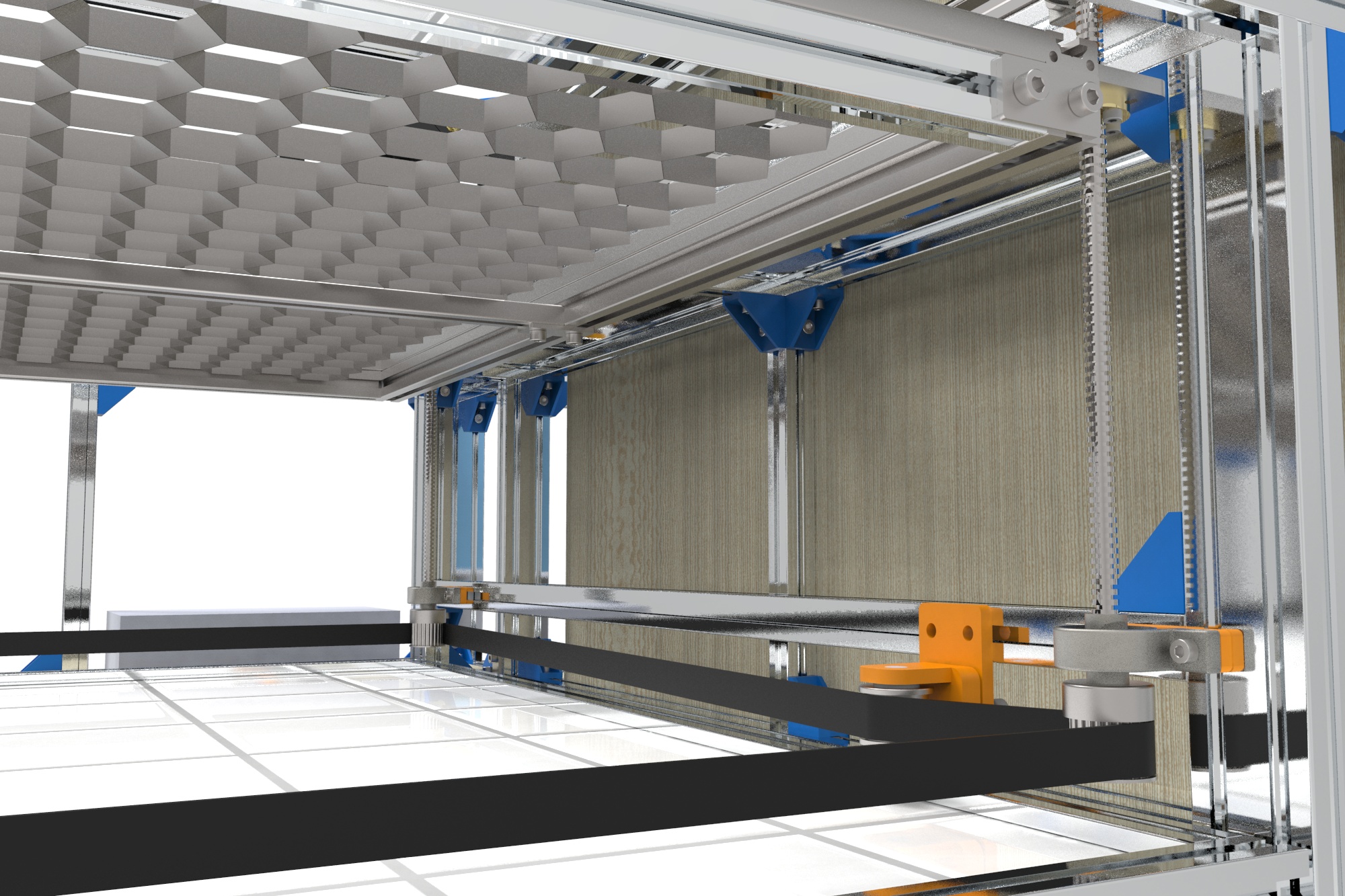

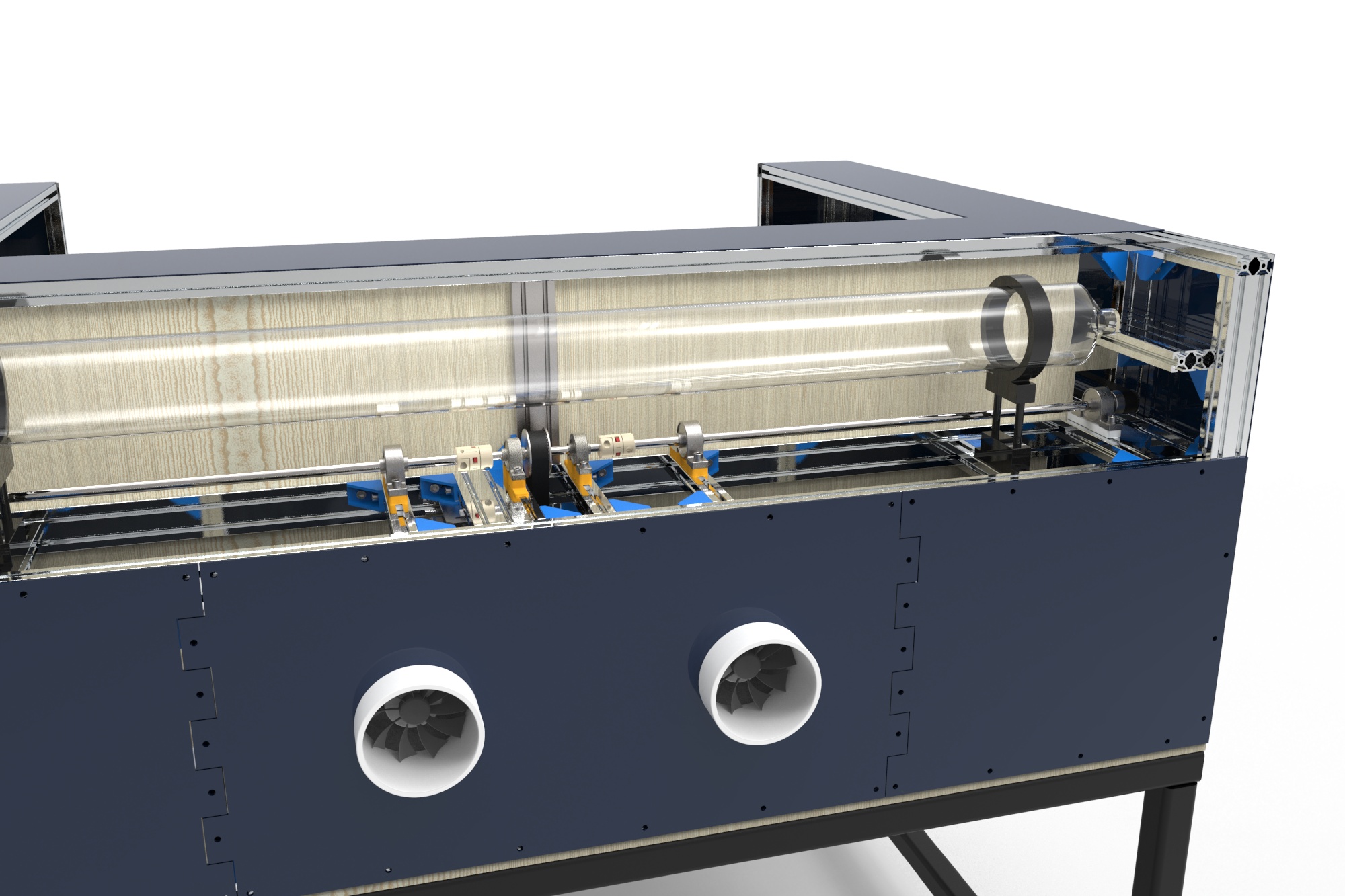

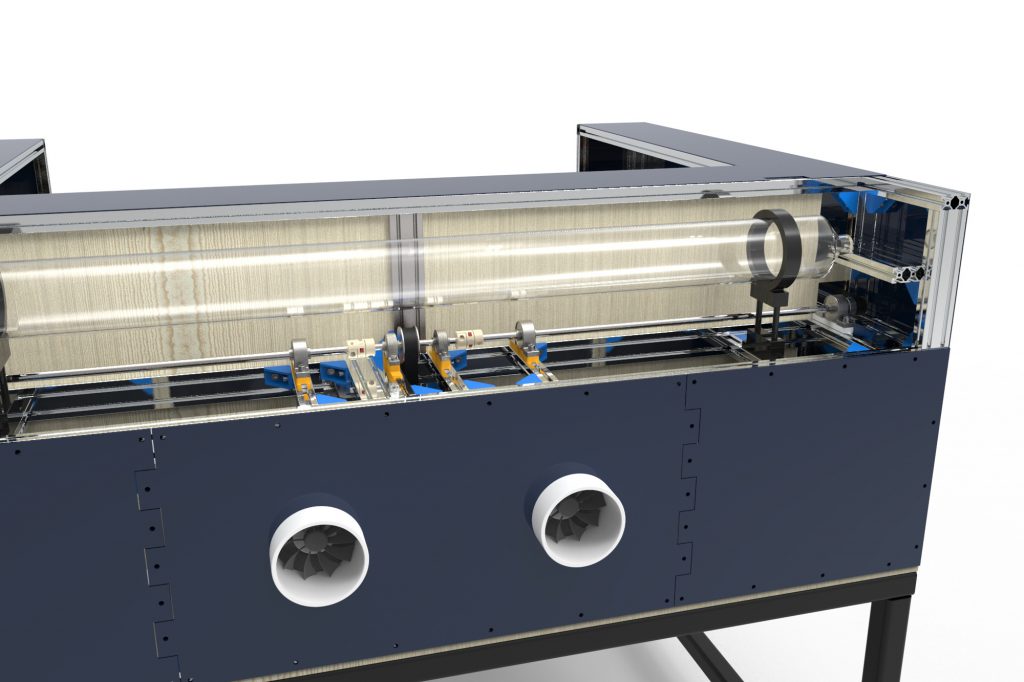

- 80w CO2 laser with the ability to fit a tube up to 120w

- Garbage tray for easy cleanup.

- Garbage tray with a hard, inflammable material to minimize any chance of accidents. (like the laser staying open, and burning the base)

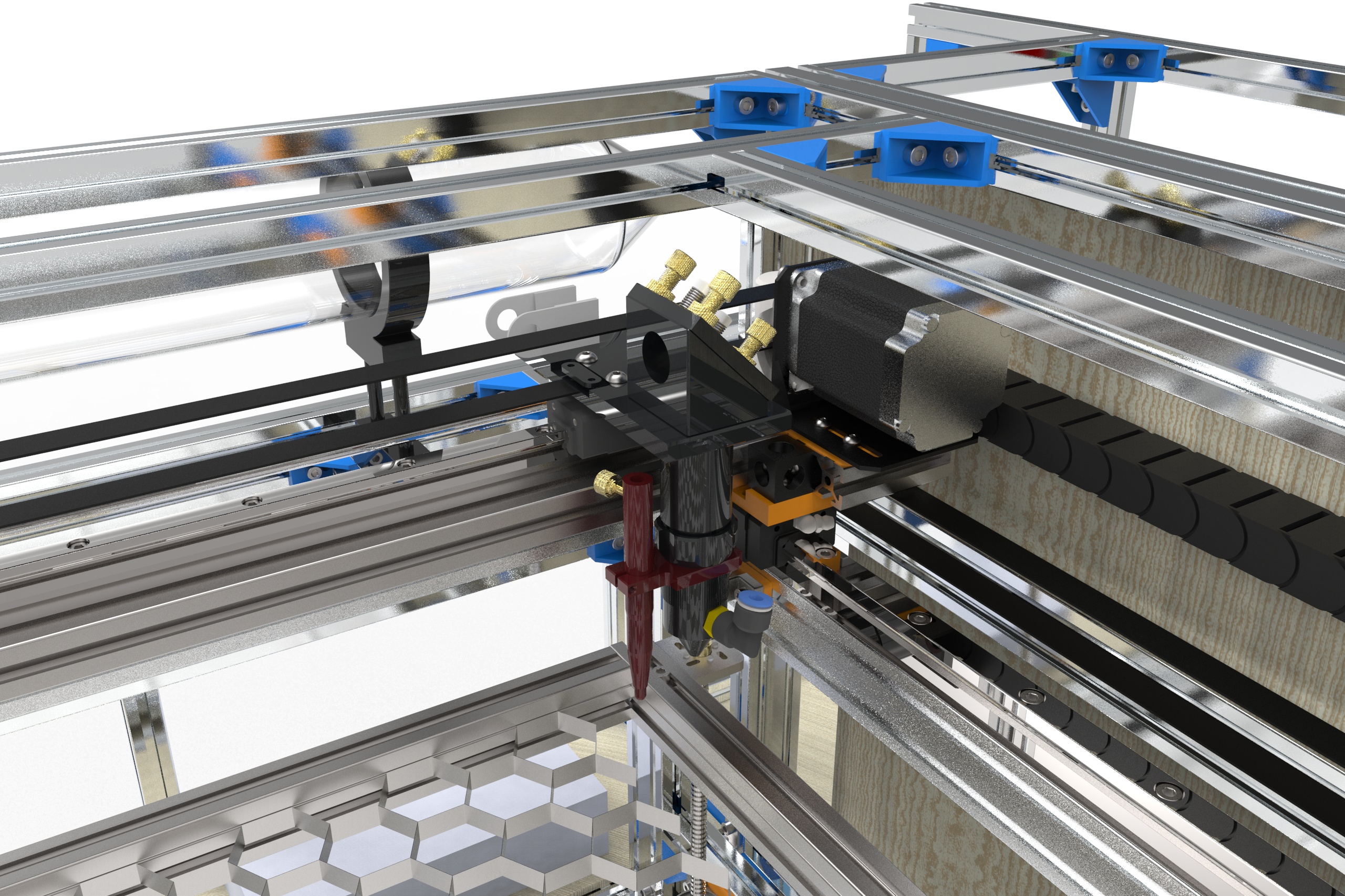

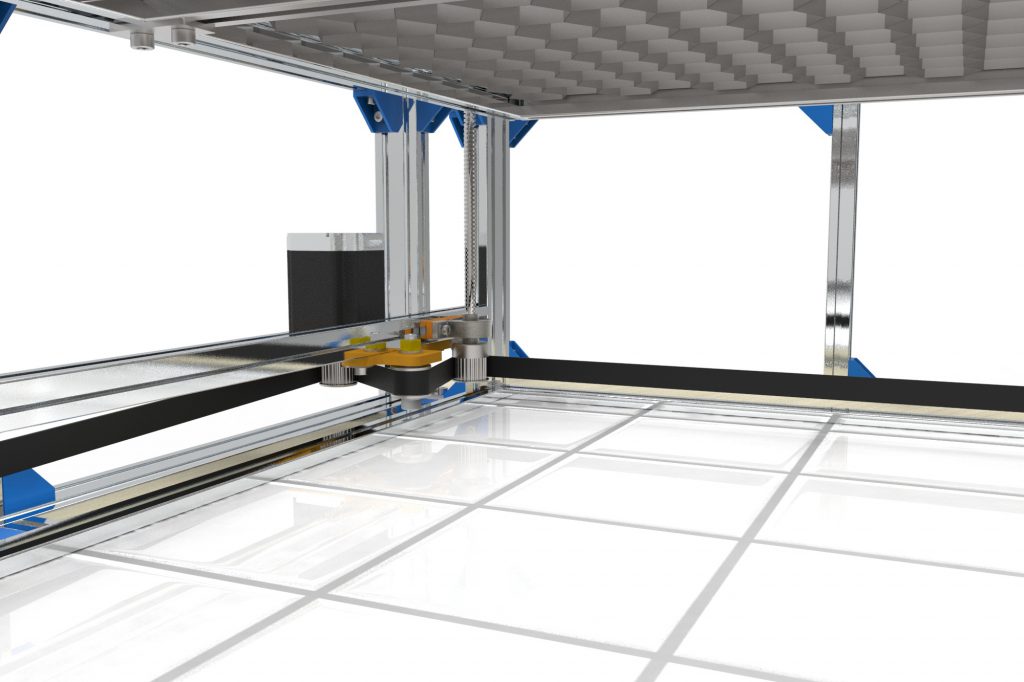

- Z axis for beam autofocus

- Adequate ventilation system.

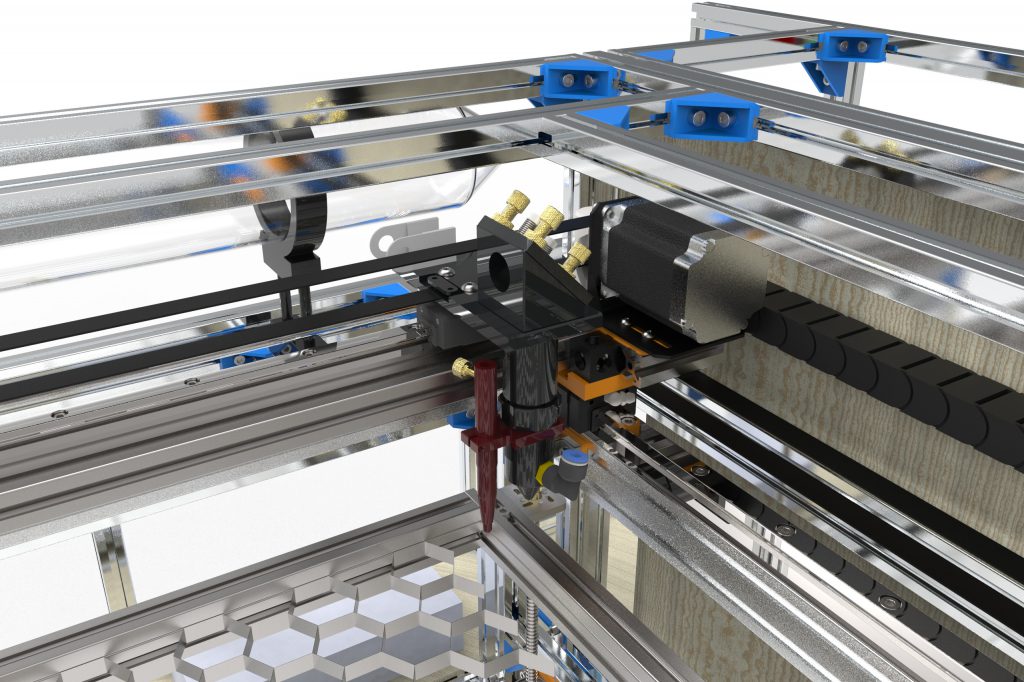

- Closed loop stepper motors to minimize any chance of lost steps and for increased engraving speed

- X-Y axis on linear rails

- 3000-3500E budget

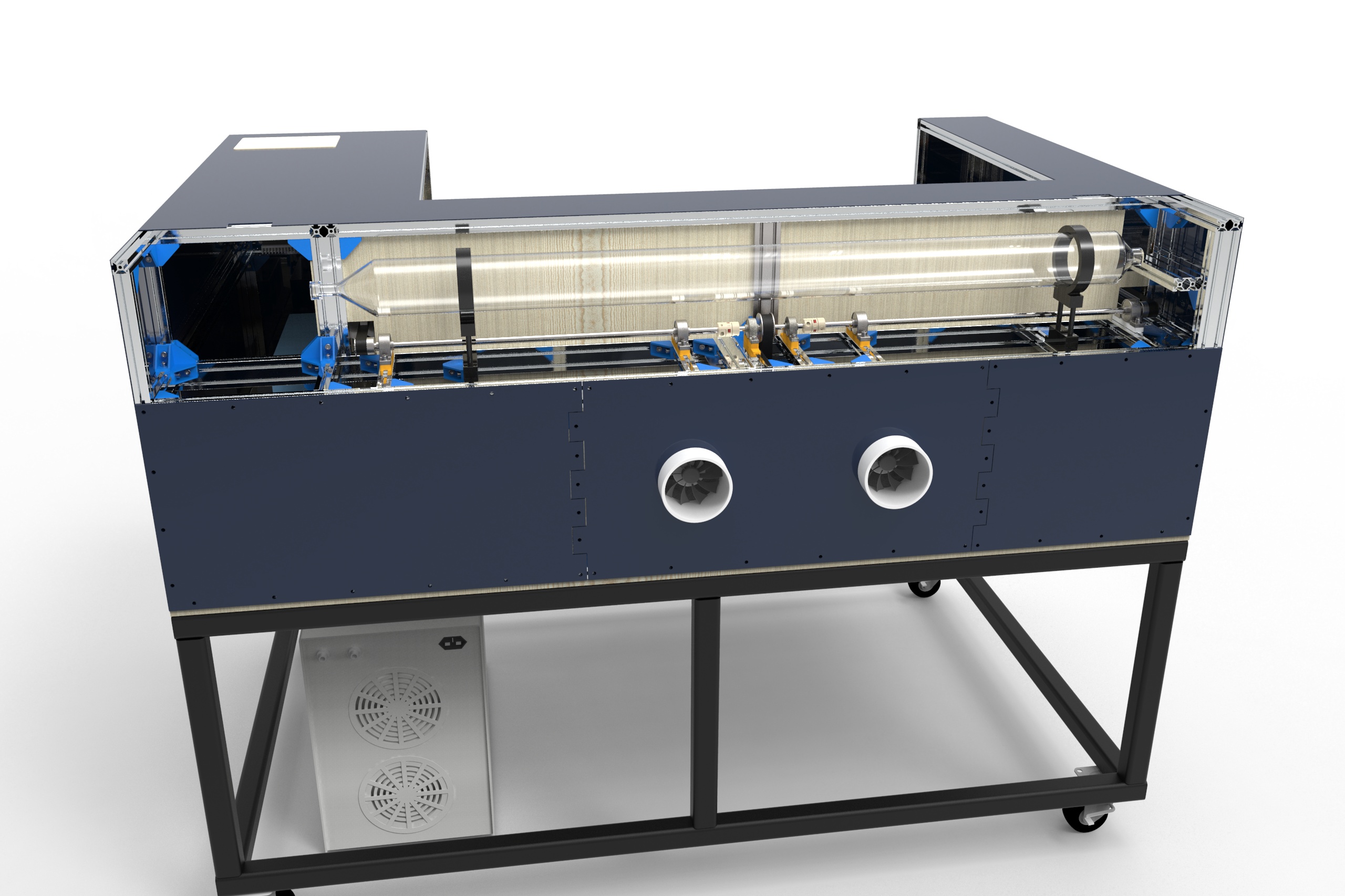

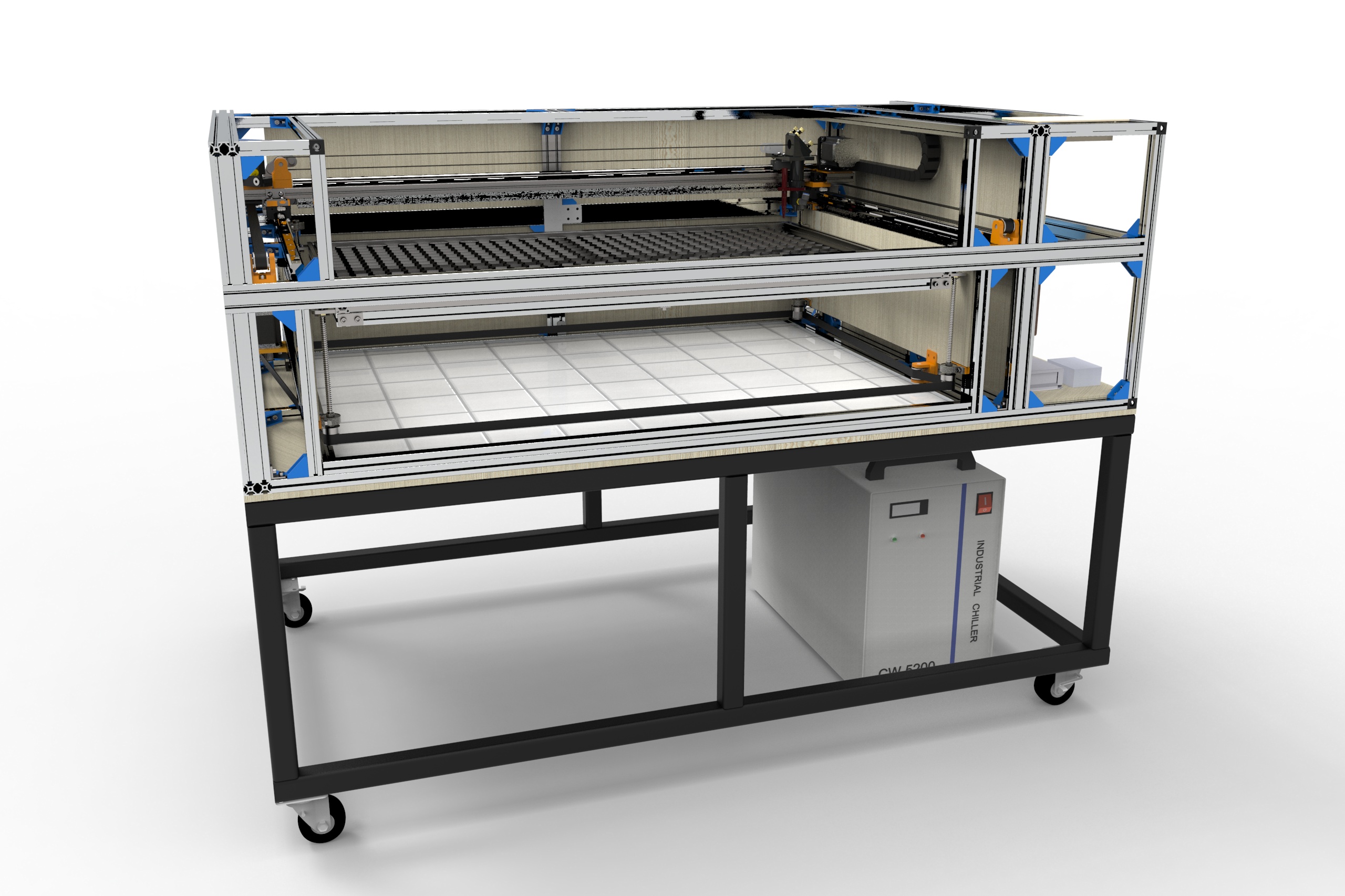

This is the result:

Outside dimensions are 1.5 x 1 x 0.5mm, not including the base.

While all the components have been purchased, the assembly hasn’t been completed yet. When its ready i will also release the drawings on the open source community.

Disclamer about the renders: there are some obvious mistakes because of some performance issues that i encountered on FREECAD. Not all bolts are visible/or in the model. The energy belt on the X axis is unconstrained. The First laser mirror is missing from the model.

SLIDESHOW: